History

The history of wire starts with Jewelry. Ancient jewelry was commonly chains and decorations that was made out of wire. Historians aren’t completely sure on how the first wires were made but it is assumed that they are made from strips of metal that were pulled through stone beads. Strip drawing was first observed in Egypt’s second dynasty. Strip wire mining was superseded by drawing in the old world between the 8th and 10th century. Square and hexagon wires were made using swage techniques. This consists of a metal rod being struck between grooved metal blocks or between a grove punch and a grooved metal anvil. This process dates back to back to the 2nd millennium BCE in Egypt and in the bronze/iron ages in Europe. The first wire mill in Great Britian was founded in Tintern by Company of Mineral and Battery Work in 1568.

Different Types of Wires

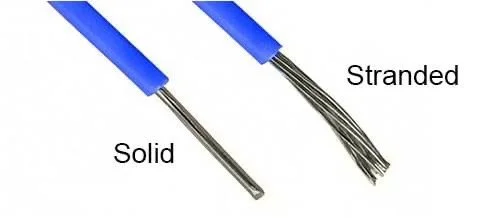

Solid

This is a solid core or a single strand of wire. Solid wire is cheaper to manufacture and provides a mechanical ruggedness. It also provides less surface area to be exposed to corrosiveness and the environment.

Stranded

This is where a number of small of wires are bundled and wrapped together to form a larger conductor. Stranded wire has the benefit of being more flexible, kink resistant, and break resistant than solid wire.

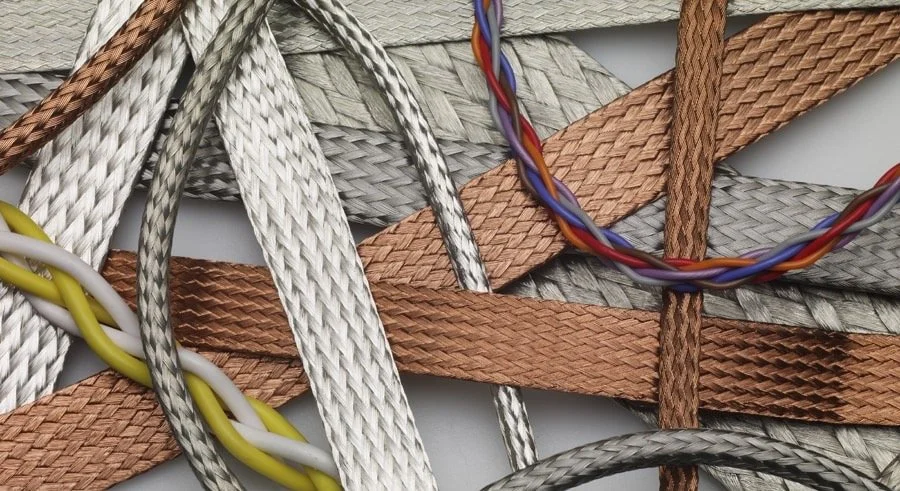

Braided

This is exactly how it sounds. Wires can be braided into multiple different patterns such as stranded (above), round braids, and flat braids.

The Process

Drawing

Drawing is the process of running rods of metal through continuously smaller dies until it reaches the required gauge. Each time these rods are passed through a die or a draw plate, it decreases the diameter and increases the length. These dies are often made up of diamond. Wires do not have to come out as circles in this process. They can be square, hexagonal, or flattened rectangular. This process can be done hot or cold. When done hot, like with copper, the dies are put into coolant and proofed with lubricant. When drawing steel, you need to do what is called a cold draw. This means the process is done at room temperature with or without the use of intermediate heat treatment

Annealing

Annealing is the act of heating the wire to the recrystallization temperature and then cooling it. This is done to improve the wire’s ductility and durability. Drawn wire is placed into an electric furnace to remove internal stresses and increase toughness. It is very important that no oxidation takes place or the coil will burn.

Tinning

If you are working with copper wire, this is an important step. For most other wires, it is not necessary. Tin is pickled and the wire is passed through it. Copper wire can also be electroplated where the wire is dipped into a chemical bath and an electrical current is passed through it.

Stranding/Bunching/Braiding

After annealing, the wire is wound onto reels. If you are making solid wire that has no coating, this is where you stop. Wires are put through a nuzzling process which gives the wire a smoother surface. Wires can also be stranded or bunched. This is the process where a lot of smaller wires are combined together. Wire can also be braided after being put onto reels.

Extruding

This is a crucial step of the process if you want your wire insulated, like in the case of electrical wires. Coating material is fed into an extrusion unit at 90 degrees of the direction that the wire passes through. Your goal at this step is to ensure that the wire is in the middle of the molten insulation. Insulating material can be made of plastic, rubber-like polymers, or varnish.