If you have been in the belting world long enough odds are you’ve ran into rough top belting. There are a variety of different kinds that are used in a variety of industries. These industries include; package handling/distribution centers, luggage/flight loader belts, synthetics/rubber/plastic manufacturing, wood industry, furniture manufacturing, farming and more. The benefits of these belts are that they cushion loads, absorb impacts, and provide friction. This friction is important in a lot of industries to prevent slippage and rollbacks. Despite the differences between the different types of rough tops, they all have similar build structures. All rough tops have a tension member, a bottom, and some sort of conveying surface with a pattern.

Impressions

Let’s first start with the different kinds of impressions since this is where the belt gets its name.

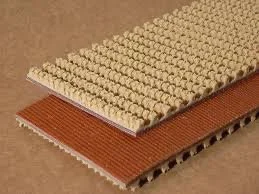

Hemp Impression/Rough Top: This is the classic rough top design that you will see 99% of the time.

Ridgetop: These belts have ridges going widthwise on the belt. They are similar to cleats except they are manufactured to the belt and not welded on.

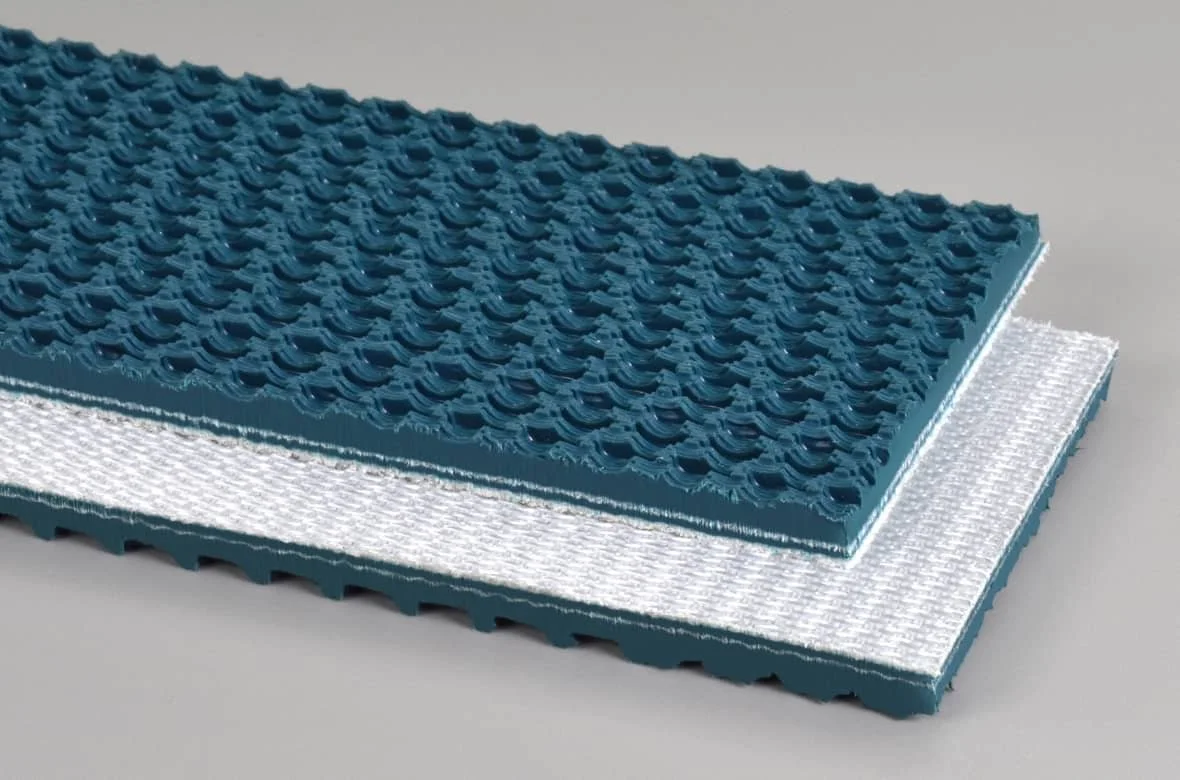

Wedgegrip/Diamond Top: This is similar to the ridgetop except the ridges intersect to create a diamond pattern. These belts are known for their very high coefficient of friction and often used for steep incline conveying.

Sinewave/Jink: This is similar to the hemp impression, however, the rows of rough top are offset to create a wave pattern.

Friction Surface: This refers to a variety of different patterns that can be impressed into the belt to ensure the proper coefficient of friction or impact resistance.

Conveying Surface Material

Rough top belts can be made from a variety of different materials. Each material has it’s own intended purpose, operating temperatures, available colors, and resistances. Rubber and PVC are the two most common materials that make up the conveying surface of rough tops. PVC is innately biologically and chemically resistant. It can also be formulated to where it is fire resistant and/or anti-static. Rubber is not so straight forward and there are several different kinds.

· Natural/polyisoprene – This rubber is abrasion, gouge, and cut resistant. It is generally used in applications where the conveying surface needs to be non-marking.

· Natural Gum – This is a type of natural rubber that is known for it higher than normal coefficient of fiction. Gum’s coefficient of friction allows it to be used in steep incline applications. It is also more durable and elastic than other types of rubber.

· Nitrile- Nitrile has enhanced oil and wear resistance. This material also has a longer service life than that of standard rough top. Therefore, people use it in applications where rough top wears down quickly.

· Butyl – Butyl is known for its resistance to heat, chemicals, and abrasion. It is also an excellent option for shock absorption.

· Styrene butadiene- This rubber has good resistance to elements, ozone, and sunlight but poor oil resistance. It is often used in outdoor applications. Styrene butadiene can also be manufactured to be flame resistant.

Tension Member Materials

Majority of the tension members that you see on rough top belting is polyester fabric. This is due to the fact that polyester is more resistant to moisture, UV light, and most importantly stretching. With that being said, there are several types. Most often, the tension member is a plain piece of polyester fabric. Sometimes, for quieter operation, there is a non-woven piece of polyester. Spiral polyester is used for ziplink applications. This is where the tension member has spirals that act like recessed lacing on a belt. This allows any part of the belt to be the splice. Impregnated polyester fabric is where the polyester is treated with other compounds such as PVC or polyurethane. This gives the tension member special attributes such as water, water, or UV resistance or extra durability. Lastly, interwoven PVC is where multiple types of fibers (including polyester but not completely) are intertwined into the carcass of the belt. This is done for increased strength. Monofilament is similar to polyester but is a single strand instead of separate strands put together. This is done to increase the flexibility of the belt.

Polyamide is more or less nylon. Not all polyamides are nylon, but all nylon is a polyamide. With that being said, polyamide tension members are softer, stronger, and more elastic than polyester. They also are better wicking when wet.

Majority of the time there will be multiple plies of this material and it is often mentioned in the name. “One ply PVC rough top” or “two ply rubber rough top.” All plies do not have to be the same. Sometimes one ply will be polyester while the other is cotton. There are also examples of polyester and monofilament plies on the same belt.

Bottoms Of The Belt

Bare is when one of the tension members IS the bottom of the belt. Quietweave is used in high speed applications where sound can be an issue. This is where one of the non-woven polyester tension members is the bottom of the belt. Skim coat is when there is a skim coat of rubber put on the bottom of the belt to protect it from rollers or other items/materials that may damage the tension member. Brushed is when a manufacturer brushes the bottom of the belt with certain materials to add resistant to elements or strengthen the belt. Lastly, a friction surface is something to increase the friction of the belt going over the conveyor system.

Splice Guide

· Step splice- done with a polyester tension member and a rubber conveying surface

· Finger splice- done with a polyester tension member and a PVC conveying surface

· Skive splice- done with a polyamide tension member with a rubber conveying surface

· Plastic rivet lacing- for when metal detectors or magnets are involved

· Rivet lacing- for thicker ply belts that are too heavy duty for clipper or unibar lacing

· Clipper/Unibar- the most common form of mechanical splice for this style of belting.