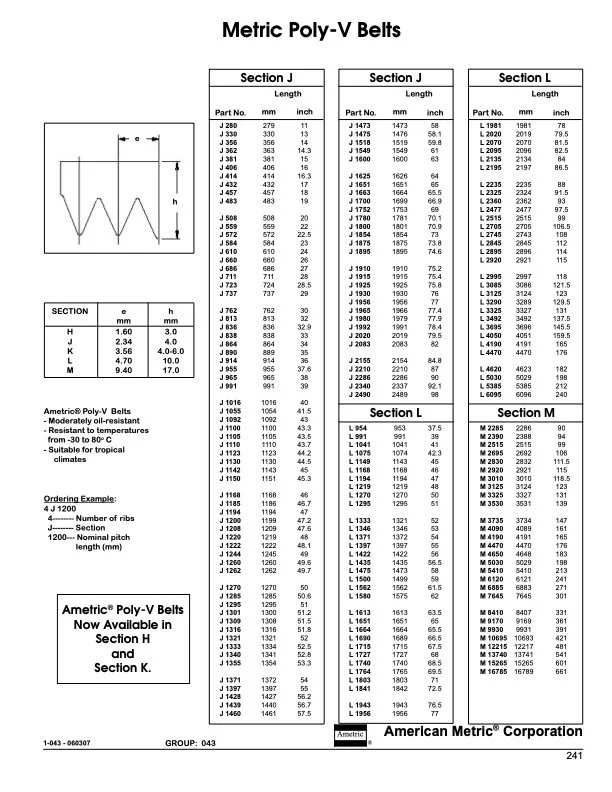

The poly-v belt is a cord reinforced transmission belt with triangular shaped rips running down the belt lengthwise. The multi-wedge rubber belt combines the best traits from both V and flat belts. Poly-V belts transmit torque through the contact of the belt’s rib flanks with that of the pulley grooves. These belts are often used to drive several peripheral devices at the same time. They offer better protection for all reinforcement cords, achieve an even load distribution, and are meant to have better surface contact than V belts or flat belts with a single cord. Anti-static options are available if needed.

What Is The Best Haul Off/Puller Belt?

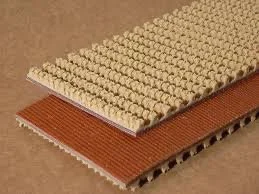

In one of our previous articles, we discussed the process of manufacturing wire. Now it is time to talk about the belting side of things. Haul-off and puller belts are the most important belts when it comes to manufacturing wire. These belts are critical in the extrusion process. Haul-off/Puller belts all have a pretty similar make up; a poly-v structure on the pulley side, a cord tension member made of fabric or aramid (Kevlar), and then a cover made of a variety of materials. Haul-off/puller belts come in a variety of sizes with thickness ranging from 3-40mm, widths ranging from 4-40mm, and lengths ranging from 250-3700mm. Even though this article is discussing the wire industry, haul off/puller belts are also used in the plastic, window, pipe, and hose markets.

What Are The Best Tube Winder Belts?

All About Rough Top Belting

If you have been in the belting world long enough odds are you’ve ran into rough top belting. There are a variety of different kinds that are used in a variety of industries. These industries include; package handling/distribution centers, luggage/flight loader belts, synthetics/rubber/plastic manufacturing, wood industry, furniture manufacturing, farming and more. The benefits of these belts are that they cushion loads, absorb impacts, and provide friction. This friction is important in a lot of industries to prevent slippage and rollbacks. Despite the differences between the different types of rough tops, they all have similar build structures. All rough tops have a tension member, a bottom, and some sort of conveying surface with a pattern.

How Are Wires Made?

The history of wire starts with Jewelry. Ancient jewelry was commonly chains and decorations that was made out of wire. Historians aren’t completely sure on how the first wires were made but it is assumed that they are made from strips of metal that were pulled through stone beads. Strip drawing was first observed in Egypt’s second dynasty. Strip wire mining was superseded by drawing in the old world between the 8th and 10th century. Square and hexagon wires were made using swage techniques.

Tube Winder Basics: How Paper Cores Are Made

Bamco strives to be a wealth of information for its customers, fellow employees, and the industry overall. The next few articles take aim at explaining important machinery that we provide belting for. On top of that we want to discuss; the belts used, vendors that provide the belts, and important attributes when it comes to the belting.

Tube winding is a very common process where belts serve multiple crucial rolls. However, before we get into the belting side of things, let’s cover the basics when it comes to tube winding. Paper cores start out as all paper products do…as paper. Parent rolls are generally brought in at the needed width . If they are not the proper size, the parent rolls are loaded onto an unwinder, slit to width, and rerolled into the rolls needed for tube manufacturing. Once the paper is at the proper width, there are two styles of tube manufacturing.

Convolute Winders

This is meant for tubes that are not spirally wound. The width of the parent roll is going to be the width of the tube. All plies are applied directly on top of each other. These cores generally have a large inner diameter and are common in the metallurgical industry

Paper is unwound from the slit roll and is fed through a series of pullies that ensure proper tension on the paper. The paper is then attached to the drum winder through a vacuum system. A lazer is used to detect the paper and apply the glue accordingly. The paper is then wound around the roll until the desired wall thickness is reached. This can be as thick as 25mm in some cases. A paper cutter then cuts the paper from the parent roll.

Spiral Winders

This is generally what people think about when they think of tube winders. These are used to create things such as; straws, paper towel rolls, toilet paper rolls, tape cores, film cores, textile tubes, and lid rings (like on Ben and Jerry’s containers.

Instead of one big parent roll, like in convolute winders, there are many rolls (sometimes up to 24) that are a smaller width. Each roll will be a ply and is unwound at the same time. Ply diverters are used to ensure that the paper does not get tangled up. Precision glue is then applied to the plies on an auxiliary roller.

The plies are then rolled around a mandrel at an offset or spiral. This process is done in conjunction to tube winder belts. These belts ensure accurate pressure is applied to the tube being created. The belts can move at speeds of up to 120m/min.

Once the tubes are created, they need to be cut. This can be done several different ways. First off, it can be done manually or programmed. Knives can be stationary or move using pneumatic amortization. Machines also vary in the number of knives being used. Some machines are as simple as one knife on either side of the tube that makes the cuts. Some machines are complex with 12 knives that move with the roll. It all depends on the customer’s needs and what is being manufactured.

Tube Accumulation System.

All tubes manufactured have to go somewhere. Smaller tubes, such as tape cores, may pile up in a box. Other systems might require complex accumulation to ensure proper flow and drying time for the glue.

Hopefully this gives a baseline to further discuss belting and hosing needs when it comes to keeping these machines running.

Product Spotlight: Sheet Slow Down Belts

Sheet Slow down belts or “suction belts” are critical for controlling sheet delivery and stacking at the end of high-speed printing lines. These watch-band like belts are designed with special materials and profiles to grip a sheet without marking or damaging it as it exits the sheeter. They are operating at increasingly fast speeds and as they begin to wear out you can see sheets slipping, fling off of the pile, jam, or misalign.

Are OEM belts losing you customers because of tray damage?

Tray packaging issues can not only impact a customers purchasing habits, but it also can cause contamination due to a poor tray seal. The most common and overlooked causes of tray damage is due to machines utilizing poorly designed belts. BAMCO identified this problem and worked quickly to solve it by creating it’s own version of the entrance/exit belts for the Ossid tray packers.

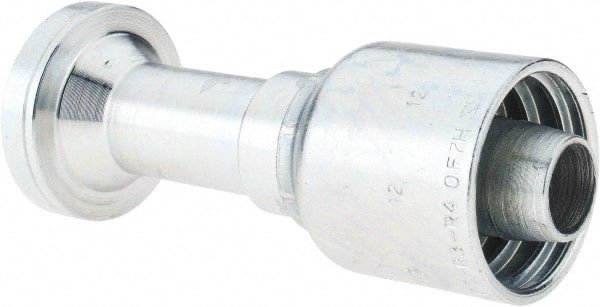

The American Standard: JIC, NPT, and O-Ring Face Seal

When dealing with hydraulics, determining which fitting you are dealing with may seem overwhelming in comparison to identifying the hose. There are usually no SAE specs when looking at a fitting. When dealing with braided hose on American equipment, you will usually be using one of three fittings; JIC, FOFS, or NPT.

How To Prevent Foreign Material Risk From Your Conveyor Belts

In 2002 the United States Department of Agriculture (USDA) listed foreign material contamination as the leading cause of food recalls. This underscores how physical foreign material contamination is a persistent problem that affects all sectors of the food processing industries. It's been estimated that the average direct cost of a recall from foreign material recall is 10 million dollars, not to mention the irreparable damage to the brand's image. This article is to provide practical guidance on how manufacturers can help avoid conveyor belts becoming a potential source of risk through prevention, screening, and looking for future solutions.

Can a V-Guided Conveyor Belt Fix Your Belt Tracking Issues?

Belt tracking issues can disrupt your conveyor system and lead to unnecessary shutdowns. In addition, it can lead to belt damage if the belt mis-tracks into a conveyor belt frame causing damage to the belt that often leads to the need for replacement. To keep a belt tracking properly a simple solution many conveyors systems use is a V-guide. This article is a guide to all the things you need to know about your v-guided conveyor belts.

Industry Innovations: The HIPPO Fitting

Top 5 Best Practices for Selecting Belts in the Meat Processing Industry

When it comes to the food processing industry, each part of any facility must meet stringent standards to ensure that the final product is safe for consumers. In any meat and poultry facility conveyor belts provide a vital role of moving products from one stage to another. The selection of these belts is key to not only the overall safety of the end product, but to improve efficiency and prevent high maintenance costs for the facility. Here are the top five best practices to make sure your facility has the best belt for their production line:

SAE Flange: Code 61 vs. Code 62 vs. Caterpillar

The other day, I was identifying a customer’s fitting and came across something that I have never seen before. A flange fitting with a clamp that only had two bolt holes. I spent all day measuring it and trying to figure out what it was. After some research, I discovered it was an old Code 62 fitting. That gave me the idea to break down the differences between the Code 61, the Code 62, and the supercat fitting.

Demystifying Hydraulic Hoses and Fittings: How to determine the correct hose and fitting for your application?

In our last article we explained how hydraulic hoses and fittings work within a hydraulic system in order to perform for different applications (Read Here). If you work in one of those industries and use a hydraulic system it is important to take into consideration the specific requirements you need from your hoses and fittings. Various applications require different hoses and fittings and selecting the right one is important for optimal performance and safety.

Demystifying Hydraulic Hoses and Fittings: Understanding Their Applications and Importance

In any application where moving heavy items is essential, industrial machinery and equipment will often use a hydraulic system to get the job done. These systems provide immense power by using extreme pressurized hydraulic oils in order to do work. To utilize this fluid power a central component of any hydraulic system are hydraulic hoses and their fittings. This article is intended to give a brief introduction to hydraulic hoses and their fittings and the diverse applications they could be used for.

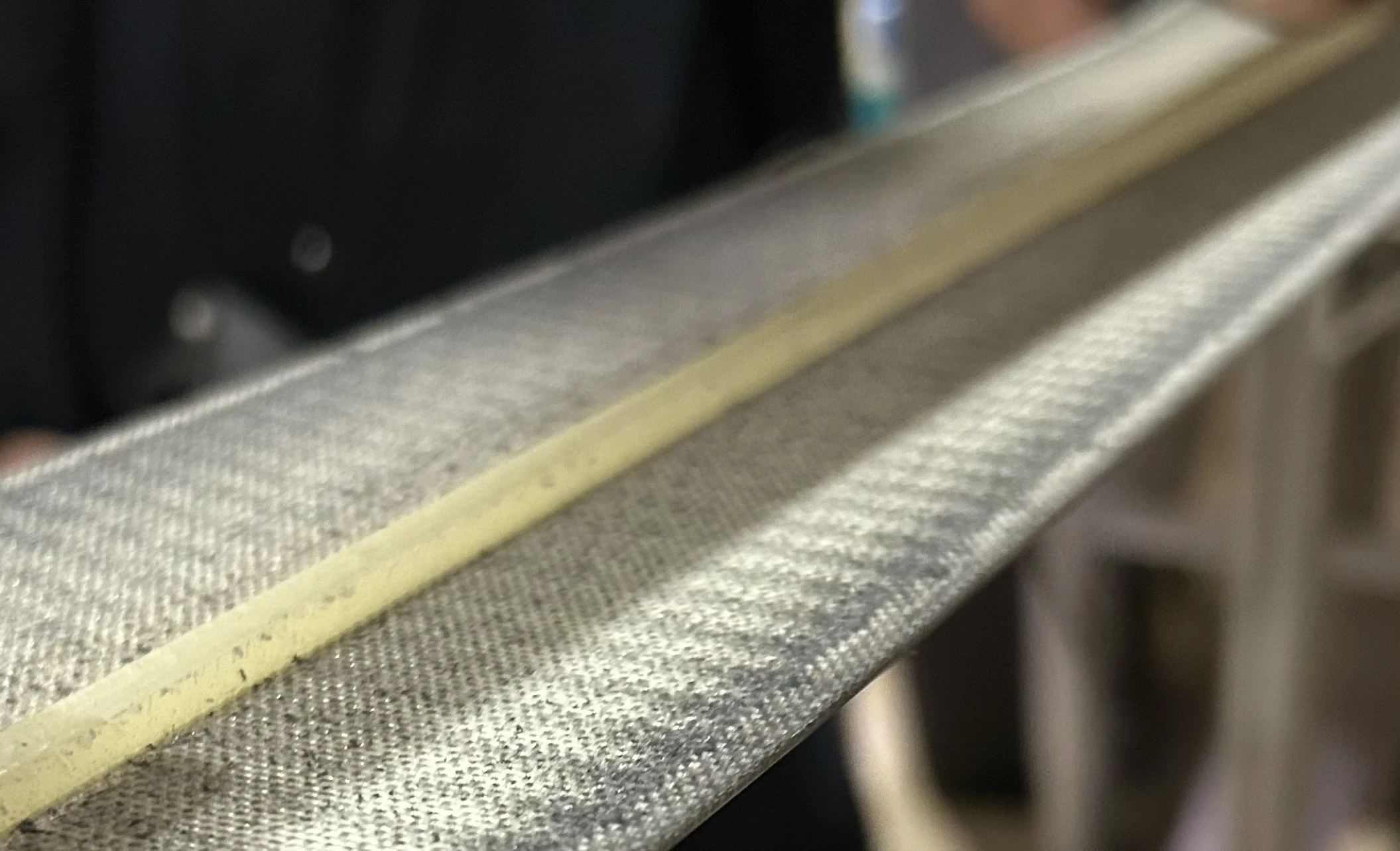

Dutchman Splice: The Solution To A Belt That Is Too Short

Recently, a customer found themselves in a situation where their rough top belts were too short. One of the few solutions that does not involve returning the belts or getting new ones is the dutchman splice. This is where you take a pre-determined length of the same material and use it to bridge the gap in the belt.

Feeder Belts: Everything You Need To Know

When it comes to feeder belts, there are a lot of different materials, brands, and characteristics that differentiate belts. It can be overwhelming. The point of this article is to compare all of the different brands and the materials sold by each brand. This way, you’ll make the best purchase for your machine.

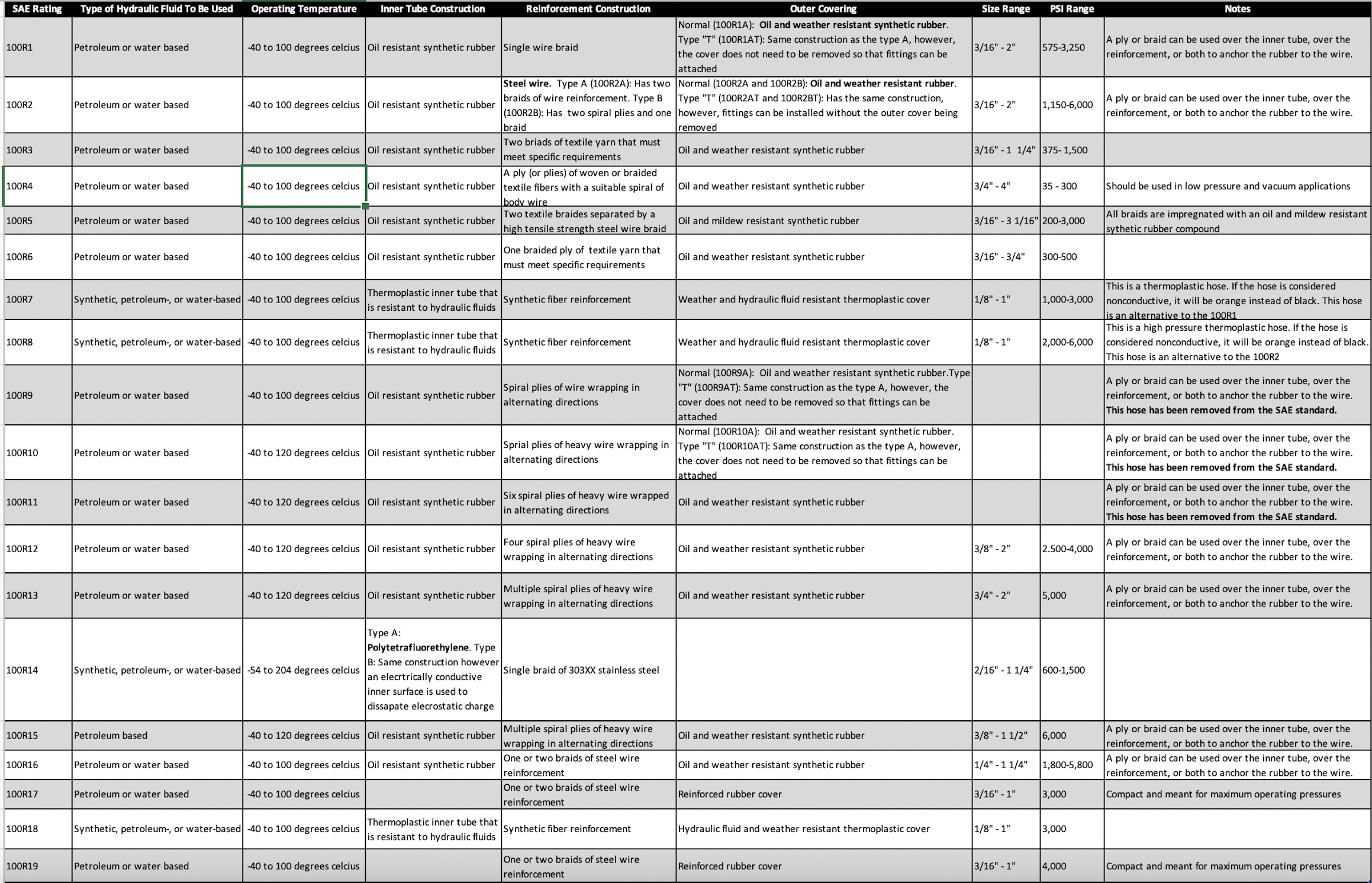

SAE Rating Guide

When you look at the layline of your hose and see an SAE rating, you may ask yourself,” What does that mean?” Long story short, this rating is used to tell you several things about the hose:

What hydraulic fluid to use.

What the hose is made out of.

The temperature that the hose can operate in.

The size range of the hose.

Other crucial facts

Bias and Hybrid Lacing: What Makes Them So Great?

In previous articles we covered splicing and mechanical splicing (or lacing) . There are two more kinds of lacing that need to be mentioned. These each have qualities of one or both of the previously mentioned splices but are tweaked for specific benefits and to solve specific problems.