The poly-v belt is a cord reinforced transmission belt with triangular shaped rips running down the belt lengthwise. The multi-wedge rubber belt combines the best traits from both V and flat belts. Poly-V belts transmit torque through the contact of the belt’s rib flanks with that of the pulley grooves. These belts are often used to drive several peripheral devices at the same time. They offer better protection for all reinforcement cords, achieve an even load distribution, and are meant to have better surface contact than V belts or flat belts with a single cord. Anti-static options are available if needed. Common uses for poly-v belts are:

Cars and buses

Outdoor power equipment

Roller conveyors

Machine tools

Medical equipment

Benefits of Poly-V Belts

Improved transmission ratio and does away with the need for step pulleys. The poly-v belt has a transmission ratio of 1:60 whereas a v-belt has a transmission ratio of 1:20. This results in 30% higher transmission power than that with ordinary v-belts given the same space taken up by the system.

Smaller structure of the transmission system. The soft belt carcasses can be used on smaller diameter pulleys. Users can also reduce the belt width for a given geometry and still produce the same amount of power. This all results in a 25% smaller space than that of a transmission using v-belts producing the same power.

One belt can drive everything. A single poly-v belt can replace up to 15 v-belts. A single serpentine set up can drive multiple different accessories. Idle pulleys and belt tensioners are also guided by the same belt producing the power.

Low heat generation and stable operation. The more ribs making contact with a pulley, the most stable the operation will be. Some poly-v belts can operate at speeds up to 40 m/s.

Heat, oil, wear resistant. Belts have the option to be anti-static.

Can be used on smooth pulleys.

Low elongation rate.

Double Sided Poly-V Belts

These belts are the same at the poly-v belts except they have ribs on both sides of the tension cords. This results in a contact surface that is twice the size of a normal poly-v belt and gives the ability to transmit power from both sides. Double sided belts do a great job at absorbing spikes and blockages. The belt design allows for necessary slippages and protects that transmission system. High torque does not harm the system. Common applications of double sided poly-v belts are:

Cylinder crushers

Dough molders and sheeters for bakeries

Agricultural machinery

Textile machinery

Gardening equipment

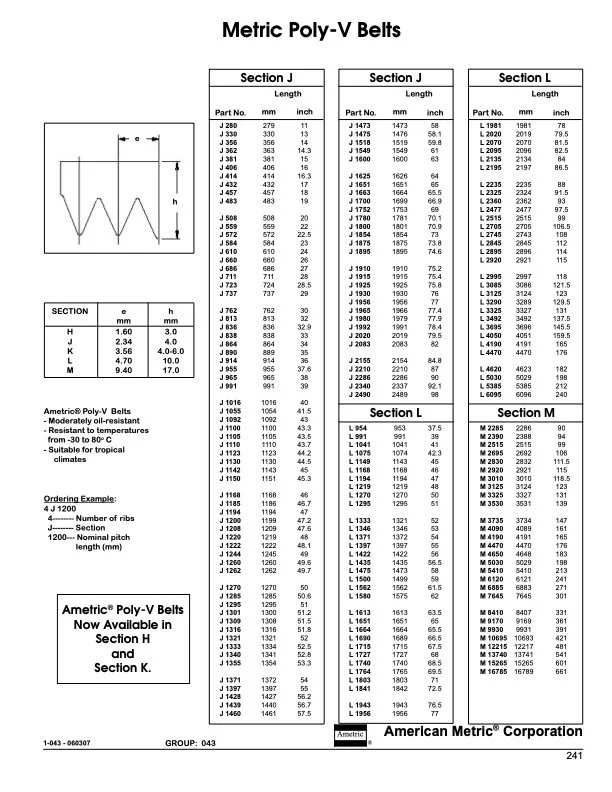

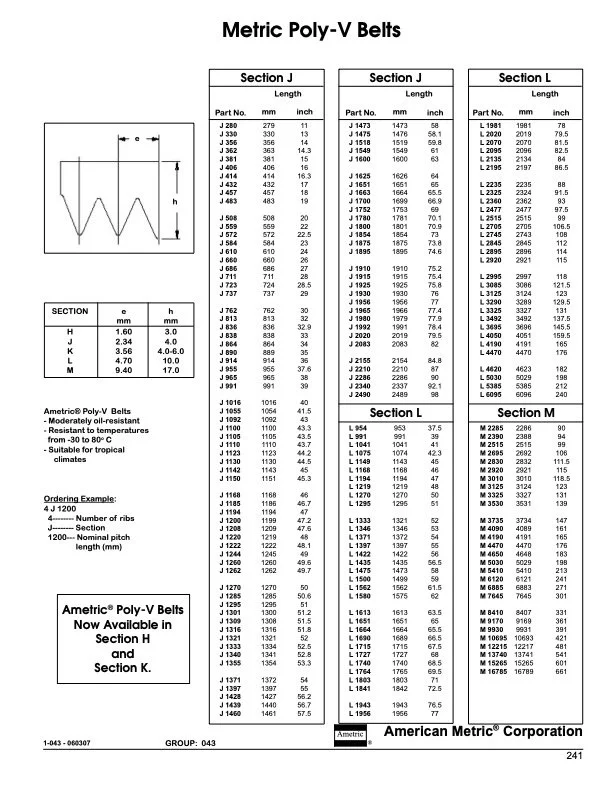

Size guide and Nomenclature

The nomenclature is always something similar to this: Number of Ribs/Pitch/Length. For example, a 2PK550 is a 2 rib, PK pitch belt that is 550mm long.