A lot of times you get a new belt in, get it installed, and get the machine back up and running just to find that the belt is not performing properly or that there are tracking issues with the belt. These issues tend to lead to belts breaking early and more costly down time when it comes to the machines. Here are six of the main causes of this so that your machines can stay running longer

What Are The Major Cost Drivers When It Comes To High Temperature and Food Belts?

What Are The Major Cost Drivers When It Comes To Timing Belts?

What Are The Major Cost Drivers When It Comes to Flat Power Transmission Belts?

What are The Major Costs When It Comes To Buying Folder Gluer Belts?

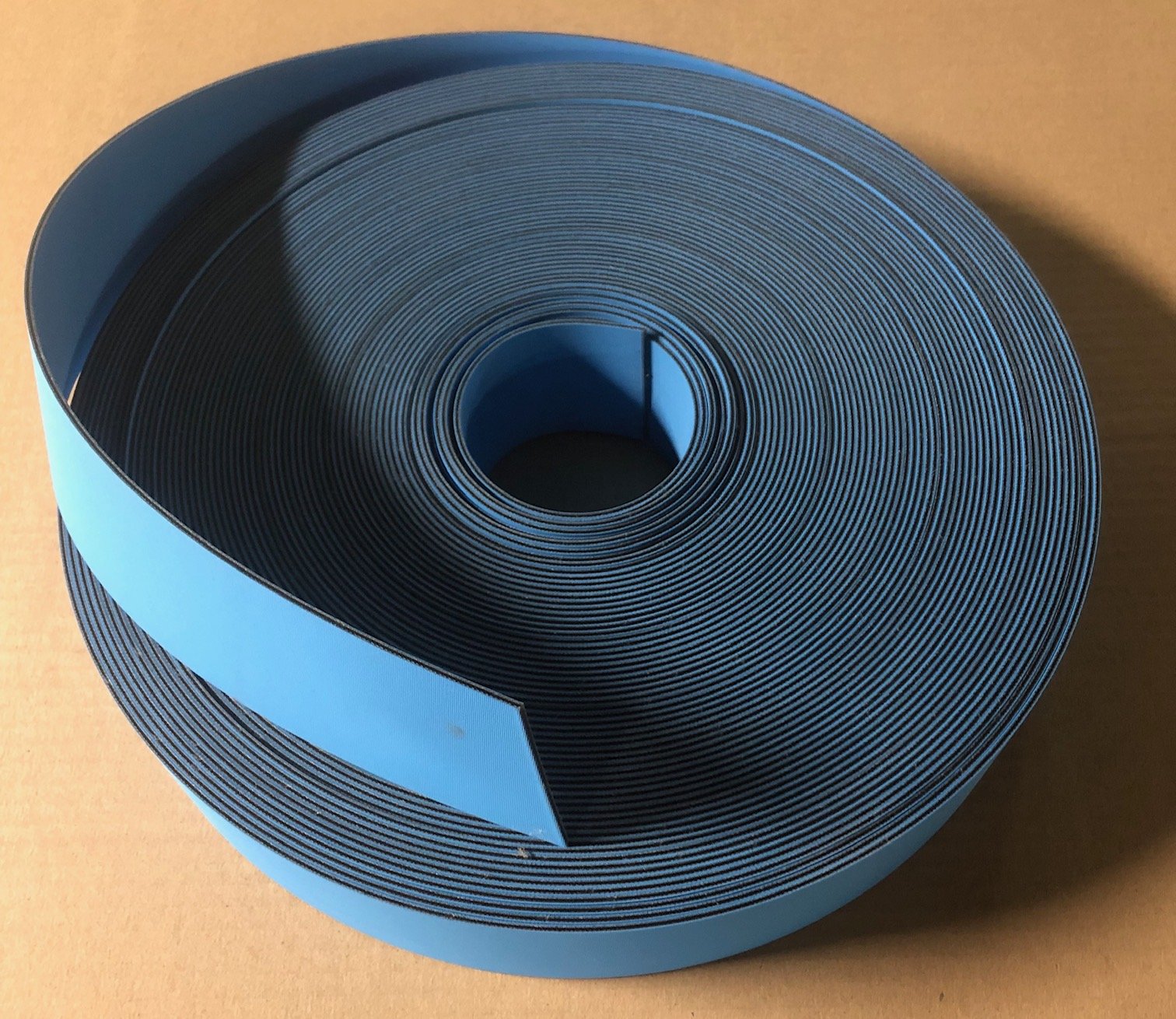

What Are The Major Costs When It Comes To Buying Conveyer Belts?

Conveyer belts, like many things in life, have a cost that is variable depending on a lot of factors. There is no fixed costs. The obvious cost drivers such as freight, selling expense, overhead, and the dimensions of the belt. However, this post is here to discuss some of the other costs drivers that are associated with purchasing a conveyer belt.